This article takes an in depth look at Ultrasonic Flow Meters.

You will learn more about topics such as:

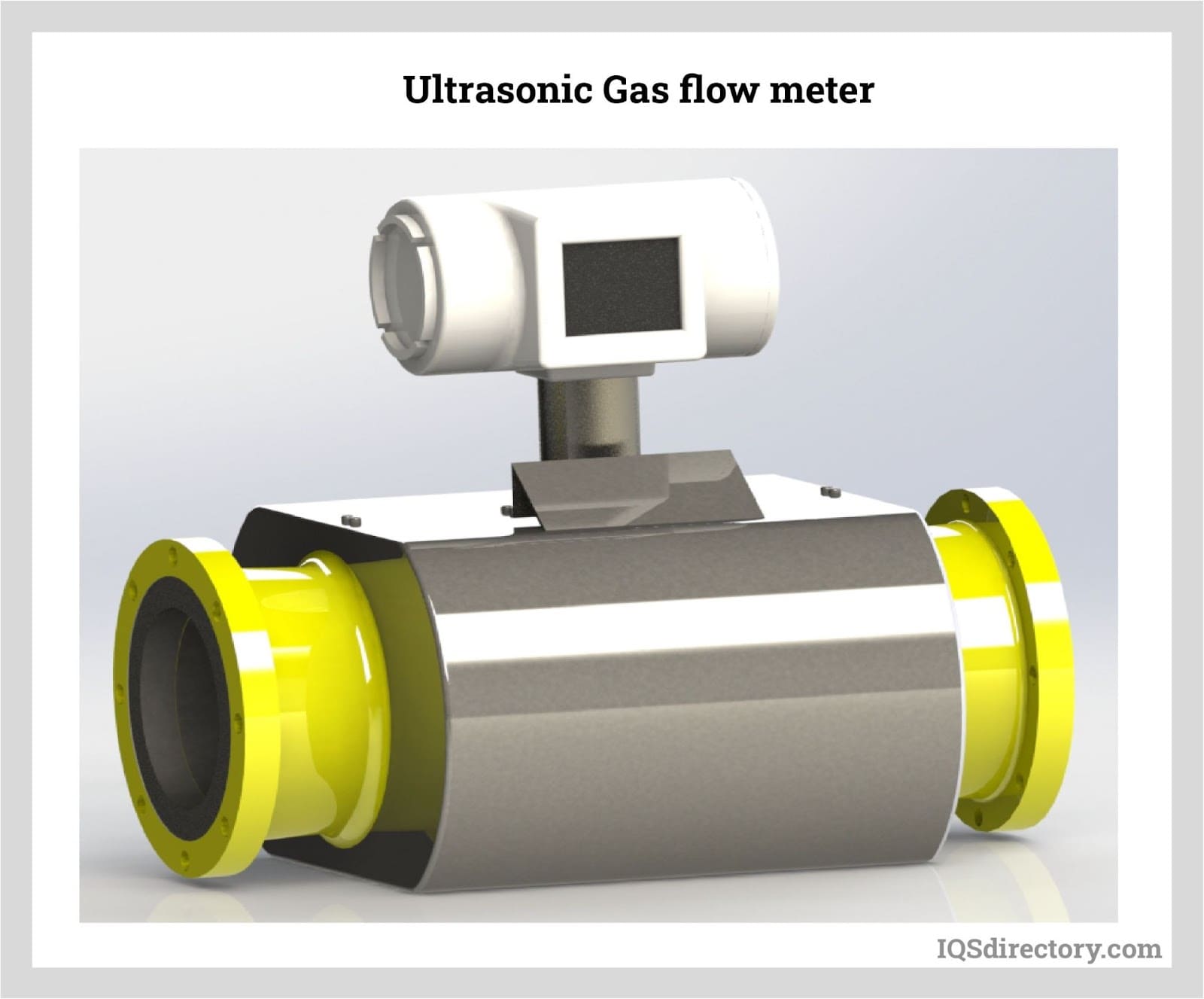

An ultrasonic flow meter measures the flow rate of a liquid or gas by emitting ultrasonic waves across a pipe in both the flow direction and the opposite direction. By analyzing the difference in wave travel times, the meter calculates the flow rate. It features two transmitters and two receivers, each positioned on opposite sides of the pipe at a specific distance to ensure precise measurements.

Ultrasonic flow meters offer high precision with an accuracy of ±1%, making them crucial for custody transfers. The clamp-on model is non-intrusive and installs easily by attaching to the pipe's exterior. Unlike other flow meters, ultrasonic models have no moving parts, offering versatility and bidirectional measurement capabilities.

The first ultrasonic flow meter was developed by a Japanese inventor in 1959, utilizing Doppler technology to measure blood flow. By the early 1960s, these meters were adapted for industrial use to measure gas and liquid flow. Since their inception, they have evolved into a key product for many instrument manufacturing companies.

A flow meter measures the volume of liquids and gases to ensure precise flow control. It is essential in many industrial applications, including chemical manufacturing, where accurate readings are crucial for production processes.

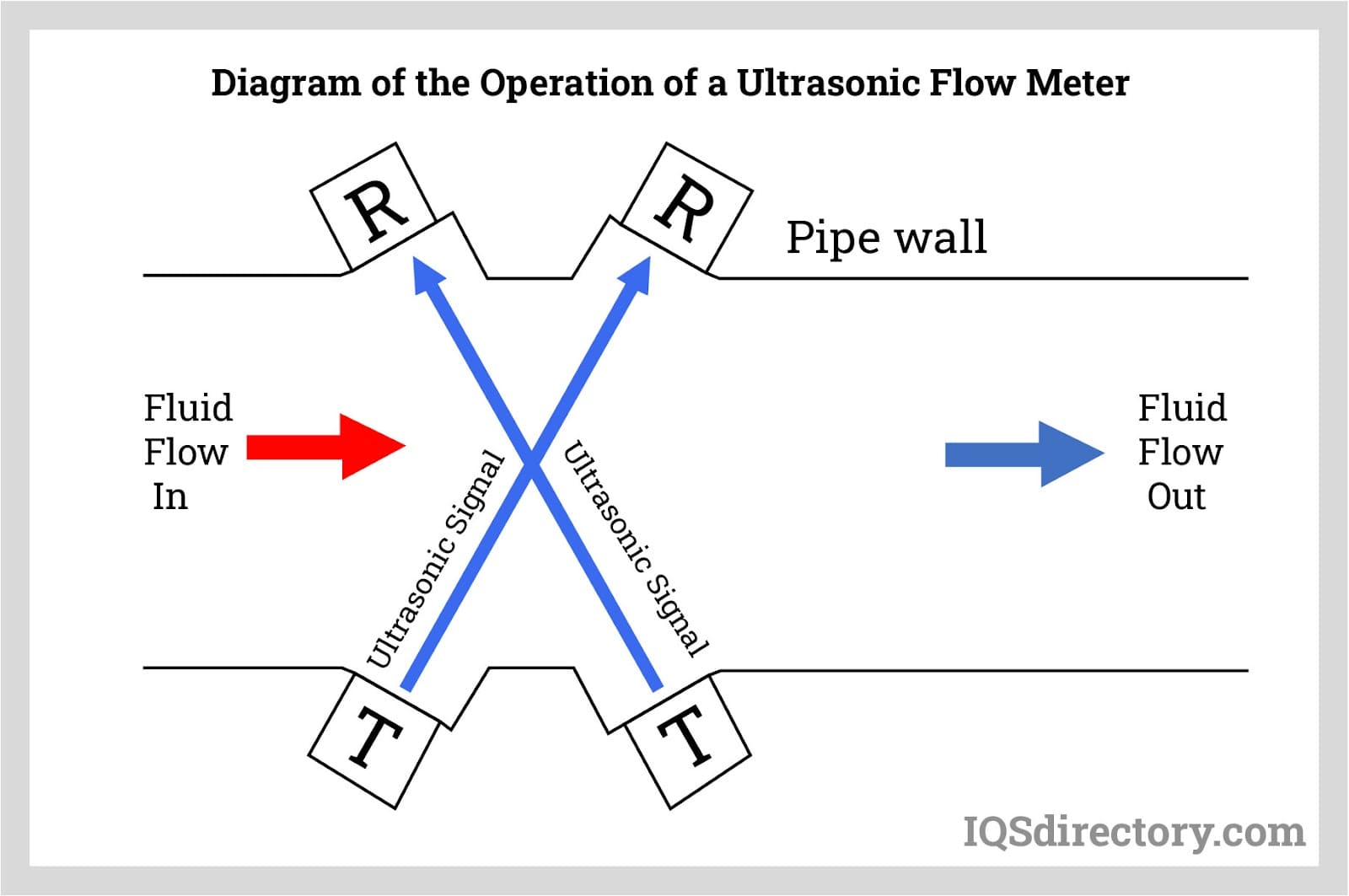

An ultrasonic flow meter measures flow using acoustic sounds and employs two main methods: transit time and Doppler shift. The key difference between these methods lies in how they acquire directional measurements. The transit time method sends sound waves diagonally to the flow and measures them in both directions. In contrast, the Doppler method projects sound waves along the flow path and measures the frequency of the reflected signal.

An ultrasonic flow meter operates based on the principle that the velocity of ultrasonic wave pulses changes with variations in the fluid flow rate.

The transducer, which measures the flow rate, can be mounted either parallel to or at an angle on the pipe's side. Ultrasonic flow meters use two transmitters to emit short bursts of ultrasonic pulses and two receivers to capture these signals as they travel through the fluid.

One transmitter, known as the preferred transmitter, sends sound waves in the direction of the flow, making it advantageous for this purpose. The other transmitter emits sound waves against the flow. As the fluid speed increases, the signal from the preferred transmitter strengthens, while the signal from the opposite transmitter weakens due to its counterflow direction.

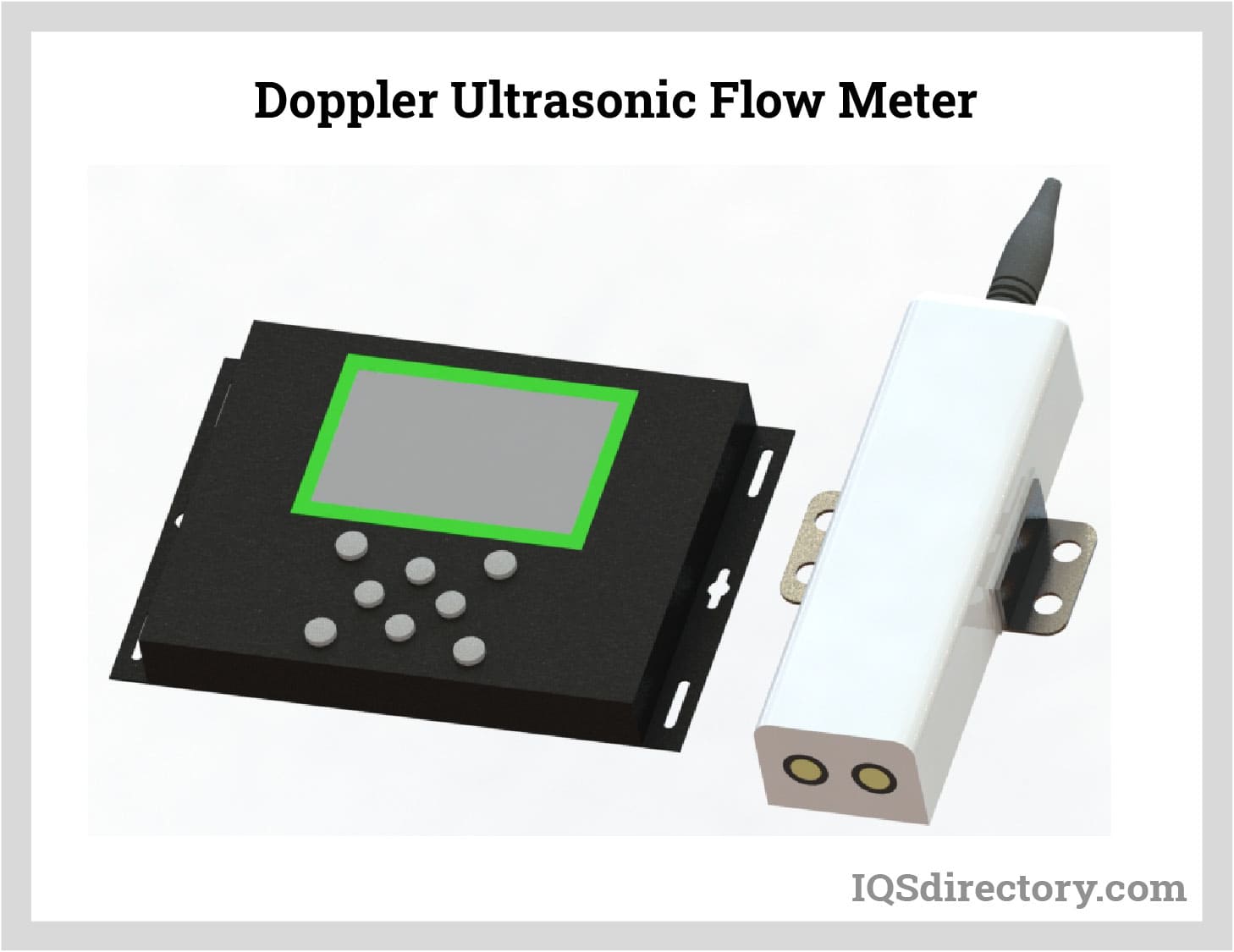

The Doppler ultrasonic flow meter measures the frequency shift of sound waves scattered by particles in the fluid. This frequency shift indicates the fluid's velocity. Doppler ultrasonic flow meters are suitable for measuring the flow of wastewater, water, and other liquids in open channels.

Transit time ultrasonic flow meters measure flow speed by calculating the duration it takes for ultrasonic pulses to traverse the fluid. The frequency of received pulses is then converted into flow rate. These meters are distinctive for their capability to measure flow rate irrespective of the flow direction.

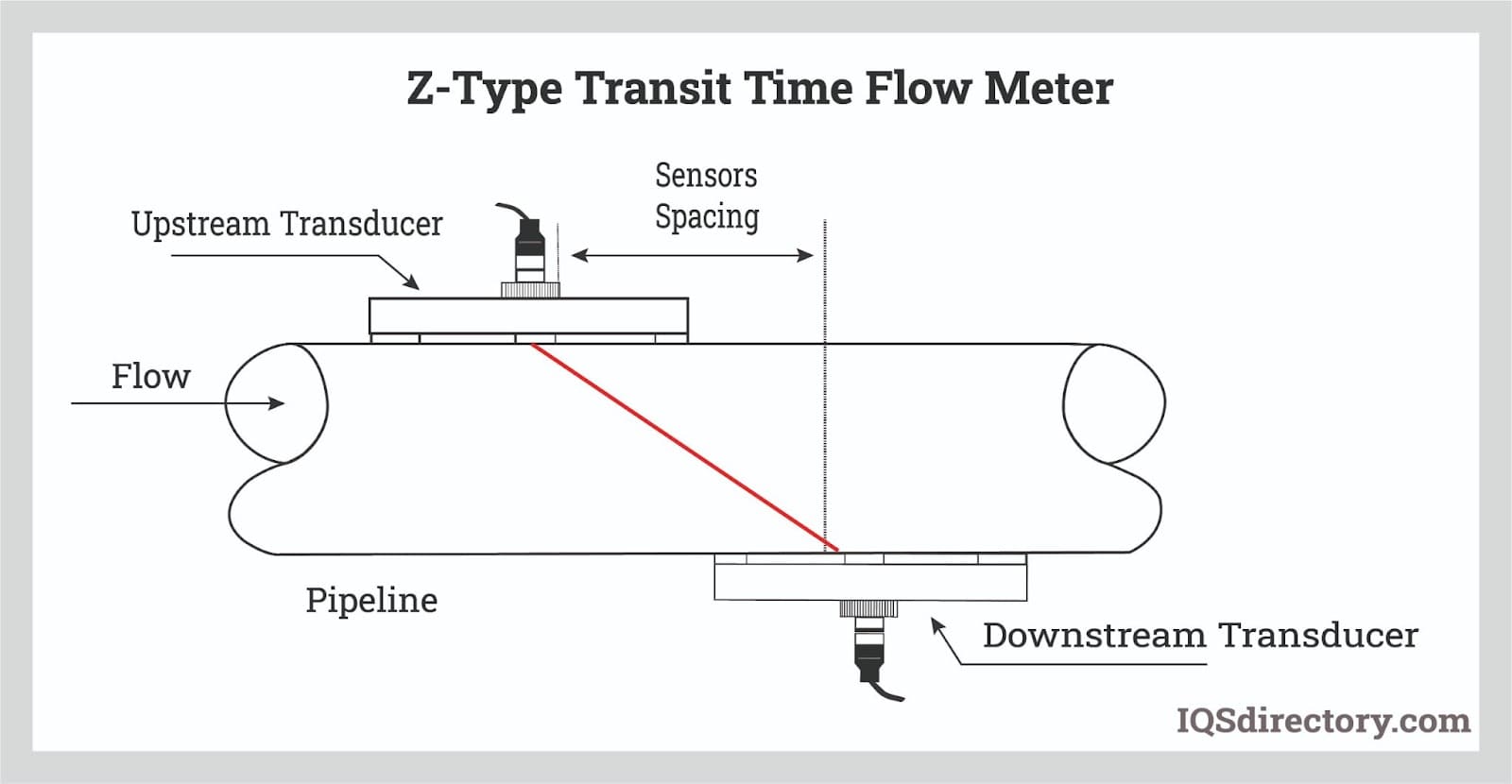

Topology is the study of spaces that remain unchanged under deformation. Often referred to as "rubber geometry," it explores how objects can be stretched, compressed, or transformed without breaking. In ultrasonic transit time flow meters, topology refers to the path taken by the ultrasonic pulse through the flow, represented by an alphabetical letter resembling the shape of the ultrasonic wave.

The ultrasonic waves move in a Z-shaped pattern, as illustrated in the diagram below.

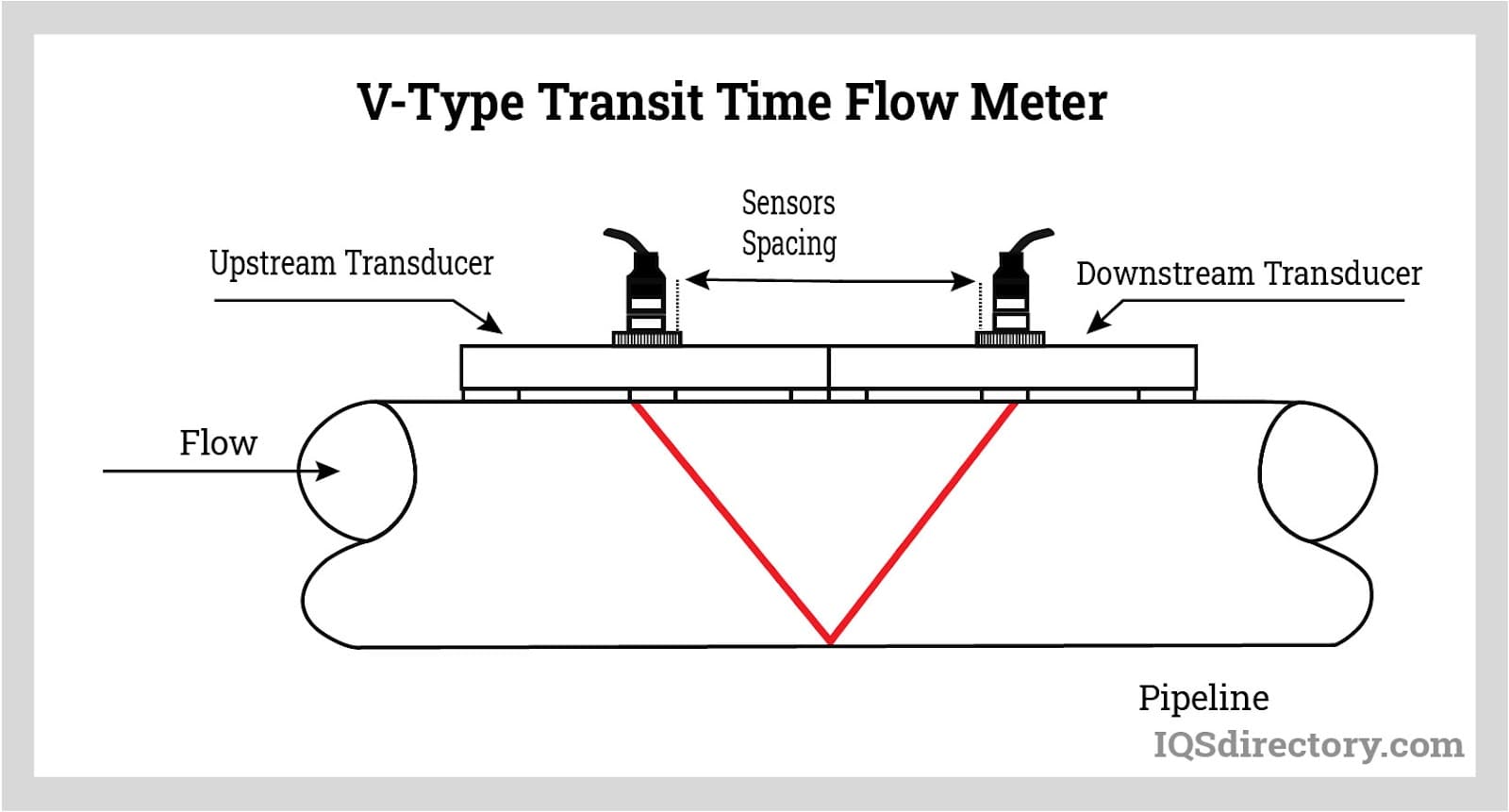

In the V-shaped transit time ultrasonic flow meter, both the receiver and transmitter are positioned on the same side of the pipe. As illustrated in the diagram, ultrasonic waves travel down the pipe and reflect back to the receiver.

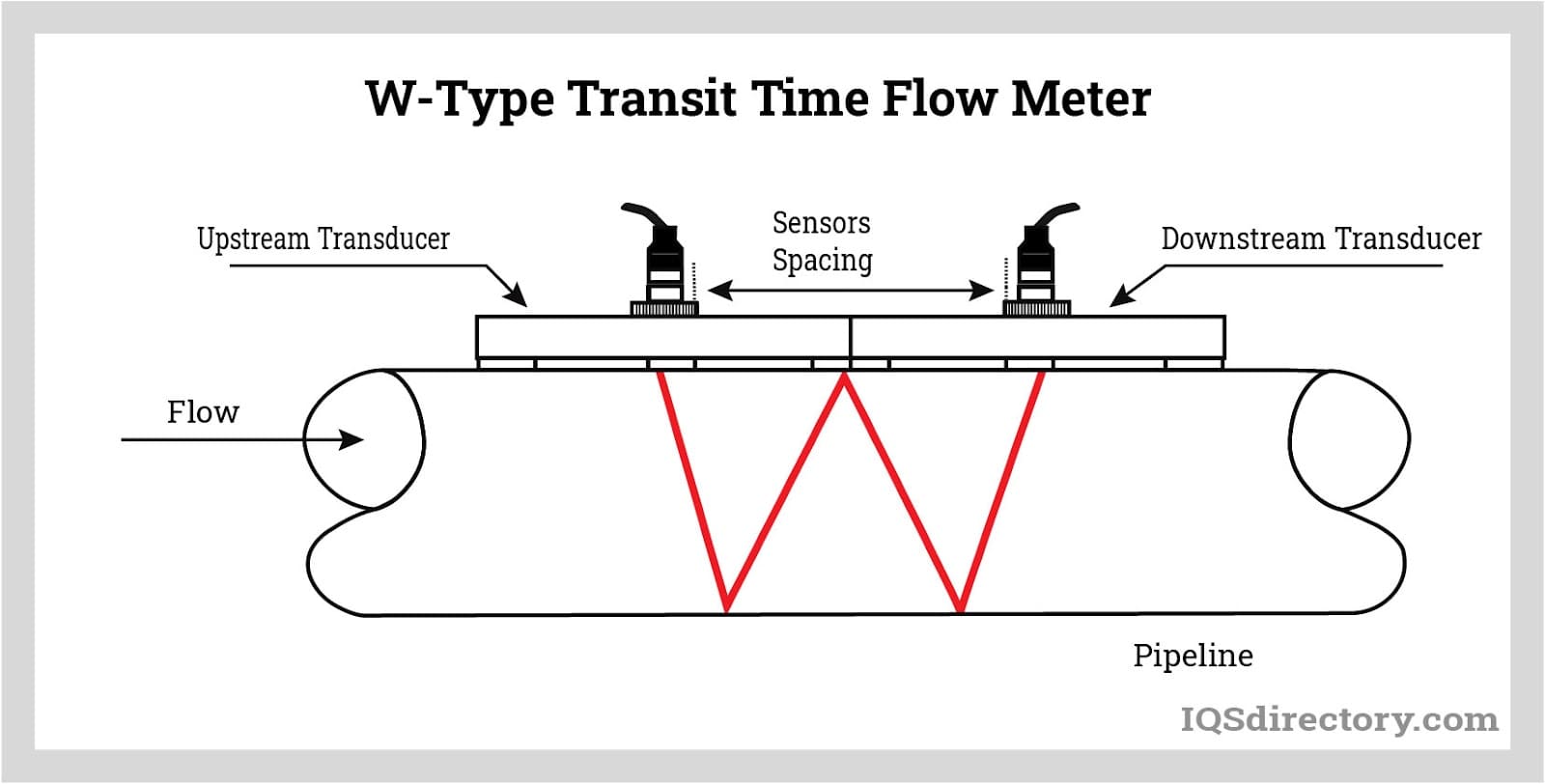

The W transit time ultrasonic flow meter directs the ultrasonic wave to bounce off the bottom of the pipe, return to the top, and then back down to the bottom again before reaching the receiver.

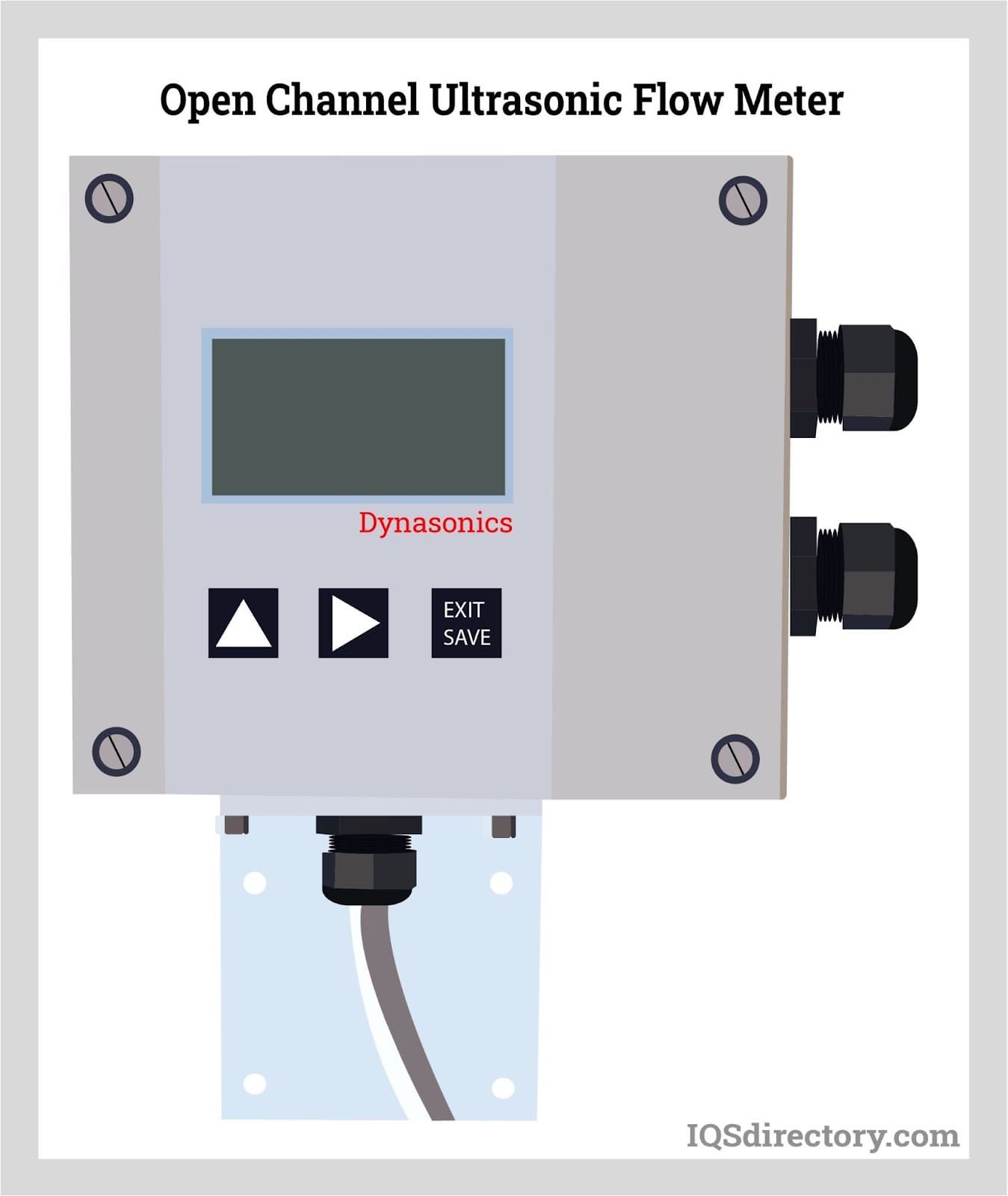

Open channel ultrasonic flow meters measure the level, flow rate, and volume of water flowing through weirs, flumes, and channels. Open channel flow meters must be non-contact, which is why ultrasonic open channel flow meters are so widely used for this application.

Unlike closed pipe flow meters, open channel ultrasonic flow meters need the channel's geometry details, including depth and width. The flow meter calculates the flow rate based on the water height. They are most accurate in channels free of sediment buildup, as sediment can significantly affect readings.

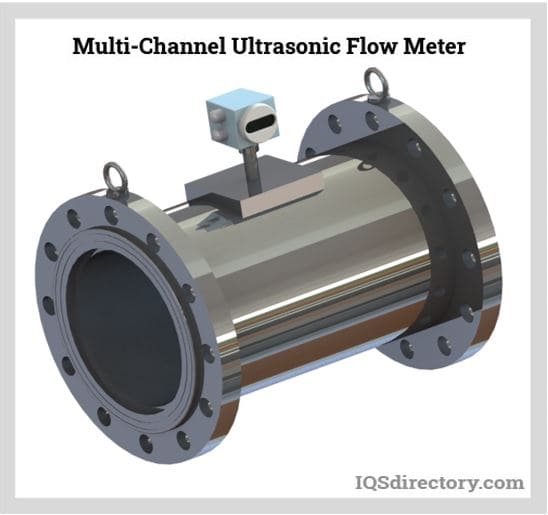

A common challenge with ultrasonic flow meters is accurately measuring flow rates when the Reynolds number, which predicts flow patterns, fluctuates unexpectedly. When only one ultrasonic beam is used, the flow rate can vary continuously with changes in the Reynolds number. To address this issue, a multi-channel ultrasonic flow meter can be employed.

The multi-channel ultrasonic flow meter utilizes four or five beams to measure multiple sound waves within the fluid flow. By comparing the transit time, or chord, of each beam, the meter calculates an average flow rate. In the four-channel method, two beams measure the flow rate at the center of the pipe, while the other two focus on the top and bottom, closer to the pipe walls.

In the image below, you can see that this two-channel ultrasonic flow meter has two transmitters at the front of the pipe and two at the rear.

There is a flow meter for any type of application, from measuring the consistency of gasses to determining how much fluid a customer purchased. The different forms of flow meters can provide precise and accurate data on volume, flow rate, mass, and quantity, depending on the requirements of the application.

Ultrasonic flow meters are highly popular for their exceptional accuracy and noninvasive operation, as they don’t require direct contact with the flowing material. The different types of ultrasonic flow meters vary based on sensor placement, attachment methods to the pipe, and the material being monitored.

A clamp-on ultrasonic flow meter is the least invasive of the various types of flow meters. They are attached to the outside of the pipe and are available in single and dual versions. With the single-sensor version, the transmit and receive crystals are placed in the same sensor body and are clamped at a single point of the pipe surface.

The dual version of the clamp-on ultrasonic flow meter features separate bodies for the transmitter and receiver sensors. Both the dual and single versions of this flow meter are compatible with specific pipe types and will not function if the pipe is lined or insulated.

Hybrid ultrasonic flow meters are the most versatile type of flow meter, capable of measuring any fluid. They are called "hybrid" because they incorporate both Doppler and transit time methods. Users can choose between these methods based on the fluid’s characteristics: Doppler is used for fluids with particulate matter, while the transit time method is suitable for clean fluids.

Hybrid ultrasonic flow meters are the most versatile type of flow meter, capable of measuring any fluid. They are called "hybrid" because they incorporate both Doppler and transit time methods. Users can choose between these methods based on the fluid’s characteristics: Doppler is used for fluids with particulate matter, while the transit time method is suitable for clean fluids.

To use an in-line ultrasonic flow meter, you need to enter the pipe parameters into the display, measure the transducer spacing, and attach the transducers to the pipe. This can be done even while the pipe is filled with fluid. The entire installation process takes only a few minutes.

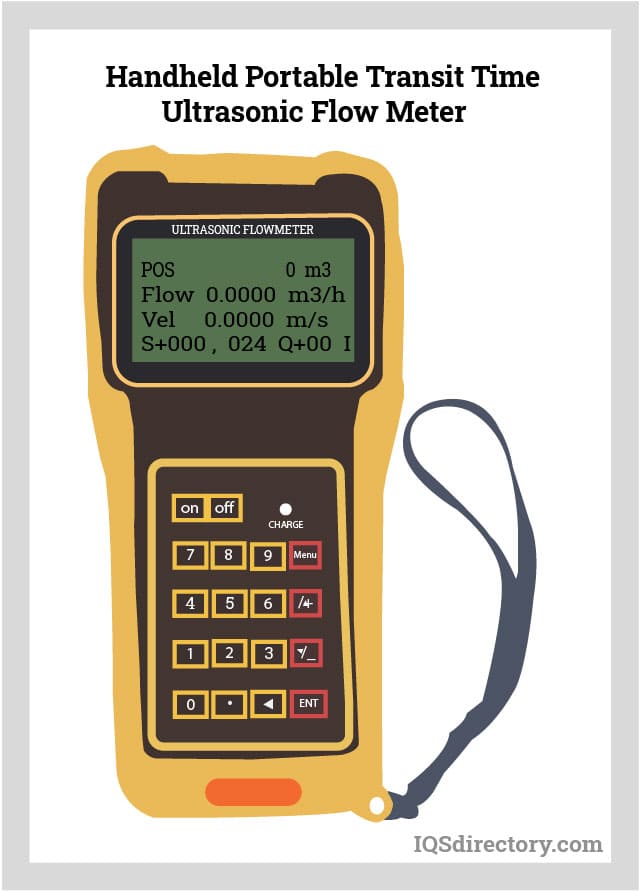

Portable flow meters vary in size, ranging from compact models similar to a calculator to larger ones akin to a laptop or notebook. They feature built-in rechargeable batteries or AC plugs for easy connection to any outlet. Data is displayed in graphs or columns and can be effortlessly transferred to other computers.

The sensors of a portable ultrasonic flow meter are connected via wires that are clamped, fastened, screwed, or magnetically attached to the pipe. To ensure optimal meter performance, the transducers are positioned at precise intervals. As with all ultrasonic flow meters, signals are transmitted through the wires into the pipe to measure the flow rate.

Radar flow meters differ from ultrasonic flow meters as they utilize microwave radar signals instead of ultrasonic waves to measure flow, mass, and volume. These meters are effective for substances with a dielectric constant greater than two, like water or ammonia, as they can deflect radar signals more significantly with higher dielectric constants. However, radar flow meters are unsuitable for materials with a dielectric constant below two, including air, vapors, gases, or foam.

A radar flow meter operates on a principle similar to that used by law enforcement to measure vehicle speed. It sends a beam into the flow, and the reflected signals return at a slightly different frequency. This frequency shift indicates the velocity and direction of the flow.

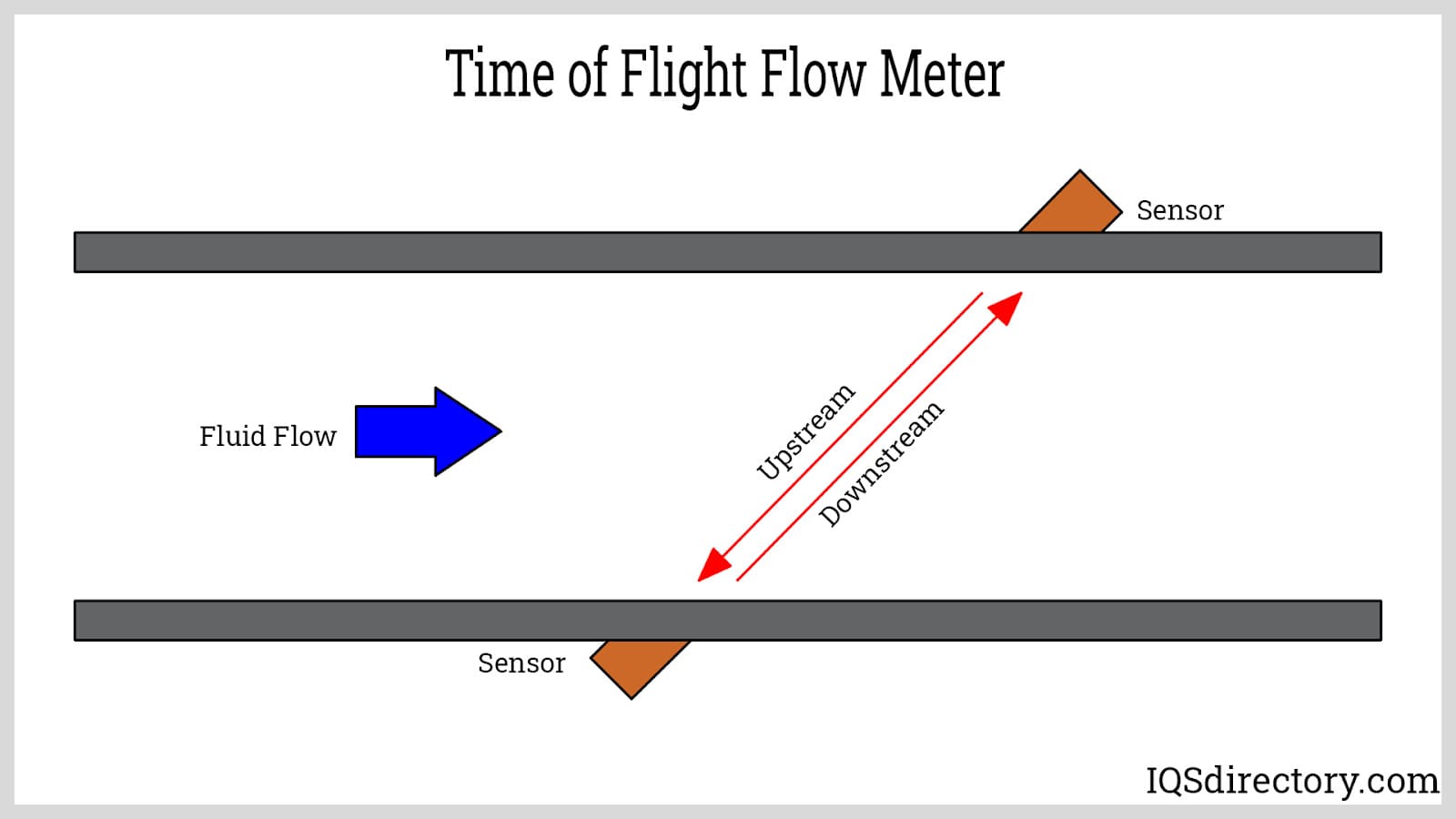

In a time-of-flight ultrasonic flow meter, sound waves are transmitted from both sides of the pipe. The wave traveling with the flow arrives faster than the one going against it. By measuring the phase shift of each signal, the fluid velocity in the pipe can be determined, as it is directly proportional to the time difference between the signals.

Accurate placement of the transducers is crucial for precise flow meter readings. Key to this process is the refraction angle of the ultrasonic signal as it travels through the pipe. To avoid signal distortion caused by air gaps, an ultrasonic couplant is applied between the transducer and the pipe.

For a time-of-flight ultrasonic flow meter to function correctly, the fluid must be free of gas bubbles, maintain laminar flow, and be clear of solids that could disrupt the signal. Unlike Doppler flow meters, which rely on bubbles or particles, time-of-flight meters are less affected by changes in fluid composition or density due to temperature or pressure variations.

A totalization ultrasonic flow meter continuously measures and records the total volume of gas, liquid, or steam flowing through a pipe. These meters are specifically designed to handle pipes containing at least 100 parts per million (ppm) of suspended particles or bubbles 100 microns (μm) or larger. Unlike standard ultrasonic flow meters, which can have their signals disrupted by particles or bubbles, totalization ultrasonic flow meters excel in these challenging conditions.

Totalization ultrasonic flow meters are used for measuring the flow of various substances, including wastewater, reactivated sludge, waste activated sludge, slurries, crude oil, lime slurries, phosphates, and pulp stock. The Doppler ultrasonic method is employed to account for bubbles and particulate matter in the flow. These meters come in several styles, including clamp-on types.

Ultrasonic flow meters are popular in industrial fluid measurement due to their use of sound to gauge flow rates and volumes non-intrusively. With no moving parts or insertion components, they require minimal maintenance, reducing overall costs.

Industries that depend on fluid flow data use ultrasonic flow meters for accurate and precise measurements. Whether for residential applications or oil fields, these meters provide crucial information on fluid supply and movement.

The first flow meter, developed in Germany, was designed to measure the flow of water. Within a year after its introduction, the technology of the flow meters spread across the globe. Fifty years later, in 1959, the first ultrasonic flow meter was introduced that used the Doppler method for measuring blood flow. In 1963, ultrasonic flow meters were introduced for industrial use.

Ultrasonic flow meters continue the legacy of early flow meters, providing accurate measurements for open channels and water flow through pipes. Their flexibility and absence of moving parts make them perfect for reliable water monitoring.

The harsh conditions of the oil industry necessitate instruments that can withstand a tough environment. Clamp-on ultrasonic flow meters, with their flexibility, are perfectly suited for oil extraction and production. Due to the high pressure and velocity of pumped oil, invasive flow meters cannot handle these demanding conditions.

Ultrasonic flow meters are installed externally, which simplifies their setup and saves time. Additionally, installing other types of flow measurement devices that require cutting into the pipe can be hazardous.

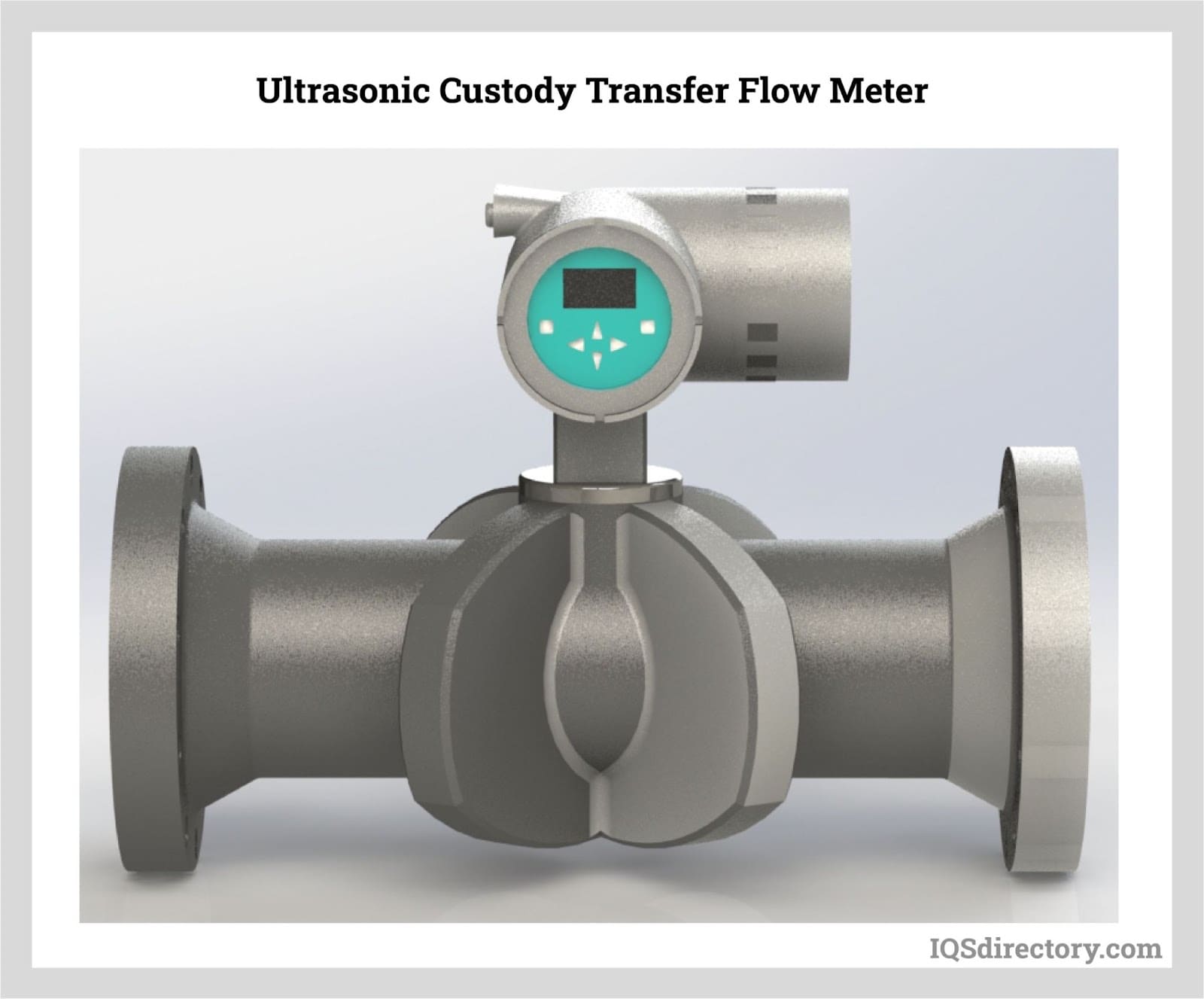

Accuracy is crucial in the custody transfer of liquids from a seller to a buyer. This process, also known as fiscal metering, involves exchanging gas or fluids between parties, with payment based on the precise quantity transferred. Given the economic stakes, accurate recording of the volume and amount of material is essential. Even minor errors can accumulate, potentially impacting the transaction's accuracy.

In 1998, the American Gas Association (AGA) approved ultrasonic flow meters for custody transfer transactions. This decision was made because ultrasonic flow meters can accurately measure volume in large natural gas pipelines ranging from 20 to 42 inches (51 to 107 cm) in diameter.

The precision and versatility of ultrasonic flow meters make them excellent for custody transfer, from oil wells to refineries and distributors. Their lack of moving parts and straightforward operation enhance their suitability for these applications.

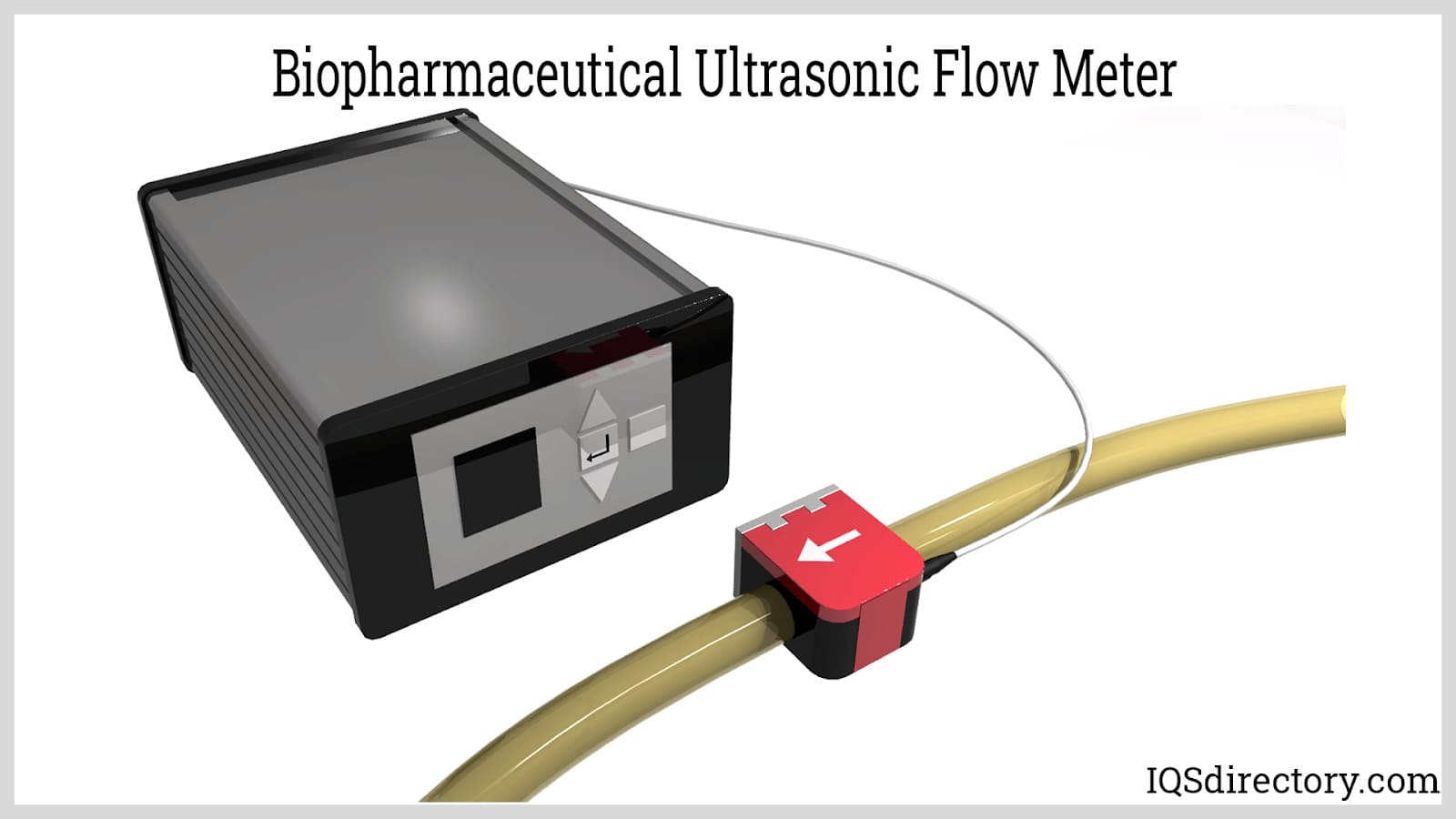

Biopharmaceutical ultrasonic flow meters are designed to measure flow rates in pharmaceutical laboratories. These clamp-on meters attach easily to flexible tubes and are media contact-free, meeting the critical needs of lab testing.

A biopharmaceutical ultrasonic flow meter measures flow rate using the transit time method. The device features a calibration table for precise monitoring and allows for customer customization of controls. In the image below, the red and black clamp on the transducer is attached to the tubing.

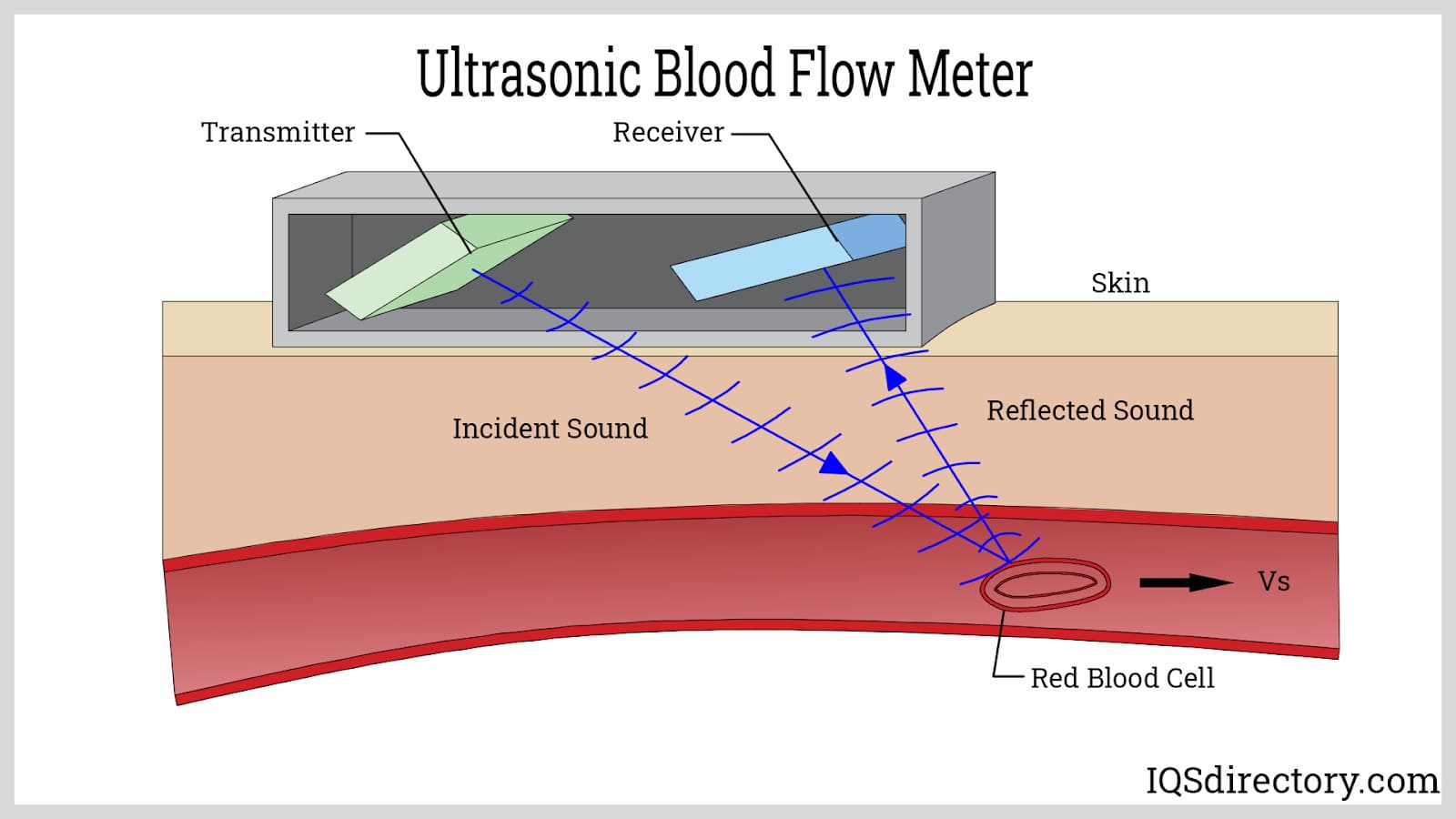

Blood flow is a crucial physiological parameter, though measuring it can be challenging. The velocity of blood flow varies significantly and is influenced by the diameter of the blood vessels. Ultrasonic blood flow meters operate on the principle of detecting the echo signals reflected by erythrocytes in the blood. As the ultrasound signal passes through the blood, it is scattered by the red blood cells before being captured by the receiver. The frequency shift in the scattered waves reveals the velocity of these moving blood cells.

The Doppler shift measures both the size and direction of flow velocity. To ensure precise readings, the ultrasound signal is pulsed. By employing range gating on the returning signal, it is possible to accurately measure both the diameter and velocity of the blood flow.

Since their introduction for industrial use in the 1960s, ultrasonic flow meters have increasingly become the preferred choice for measuring and monitoring fluid flow. Their popularity stems from their key advantages: they have no moving parts and require minimal adjustments to the pipes for installation.

Unlike more complex and intrusive flow meters, ultrasonic flow meters can be installed quickly and are often up and running in under 30 minutes. This ease of rapid installation is a key reason they are the top choice for flow monitoring.

Ultrasonic flow meters provide measurements that are unaffected by pressure, density, temperature, conductivity, or the viscosity of the fluid.

A key advantage of ultrasonic flow meters is their lack of moving parts, which eliminates the need for repairs or part replacements. Once installed, the flow meter remains motionless, yet it consistently delivers accurate and reliable readings.

By eliminating moving parts that can wear out or become damaged, ultrasonic flow meters are ensured to have a long service life. Their noninvasive nature also means there are no concerns about wear from corrosive substances or abrasions.

Whether installed inline or as a clamp-on, ultrasonic flow meters can be easily repositioned or removed as needed for different applications. Unlike permanent flow meters, which require significant effort to repair or replace, ultrasonic flow meters offer the flexibility to be used temporarily and installed only when necessary.

Ultrasonic flow meters are approved for custody transfer applications because they can effectively monitor and measure flow in large pipe sizes. They are suitable for use with pipes six inches (15 centimeters) in diameter or larger, which are too big for many other flow meters.

Ultrasonic flow meters can measure the flow of non-conductive liquids, gasses, and steam, which is a limitation of magnetic meters. For this reason, ultrasonic flow meters are used in oil and gas production, transportation, and refining since oil and gas are nonconductive.

Ultrasonic flow meters provide excellent rangeability, accurately measuring flow conditions from low to high with exceptional long-term reliability. They deliver precise and repeatable measurements, even in extreme temperature conditions.

When an ultrasonic flow meter is installed, it is calibrated to the specific conditions and environment of its location. If there are any changes or shifts in these conditions, the flow meter will detect them and adjust its measurements accordingly.

No matter how an ultrasonic flow meter is installed, it will not obstruct the flow of fluids or materials. Since it never comes into contact with the material, it does not affect the flow or the integrity of the material. This feature ensures that measurements are both safe and sanitary.